MVC – Modular Vaccines Carrier

Vaccination Cold Chain for remote locations

MVC – the Modular Vaccines Carrier is a result of years of research and onsite observations, about the challenges of transporting vaccines to remote locations around the world.The ‘Cold Chain Project’ was initiated by Satyendra Pakhalé during his 2006-2010 tenure as head of the Master of ‘Design for Humanities and Sustainable Living’ at Design Academy Eindhoven, the Netherlands as an academic research project. In collaboration with MSF – Médecins Sans Frontières / Doctors Without Borders and WHO – World Health Organization the initial plan of carrying out on-site research in Burkina Faso could not be realized. Subsequently it was realized in collaboration with Izmir University of Economics in Izmir, Turkey in 2008. Having done the field research, Pakhalé revisited this humanitarian project in the light of current conditions, where there is a massive need of effective and efficient vaccines supply chains. In current conditions, the cold chain is the only safe way of transporting vaccines over long distances. Existing cold boxes are cumbersome and bulky.

Vaccines are technological miracles, one of the success stories of medical history. They have saved millions of lives over the last decades – and prevented countless disabilities.Before they are given to children around the world, all vaccines supplied by UNICEF go through rigorous reviews by manufacturers, national regulatory authorities and the WHO to ensure their quality, safety and effectiveness.

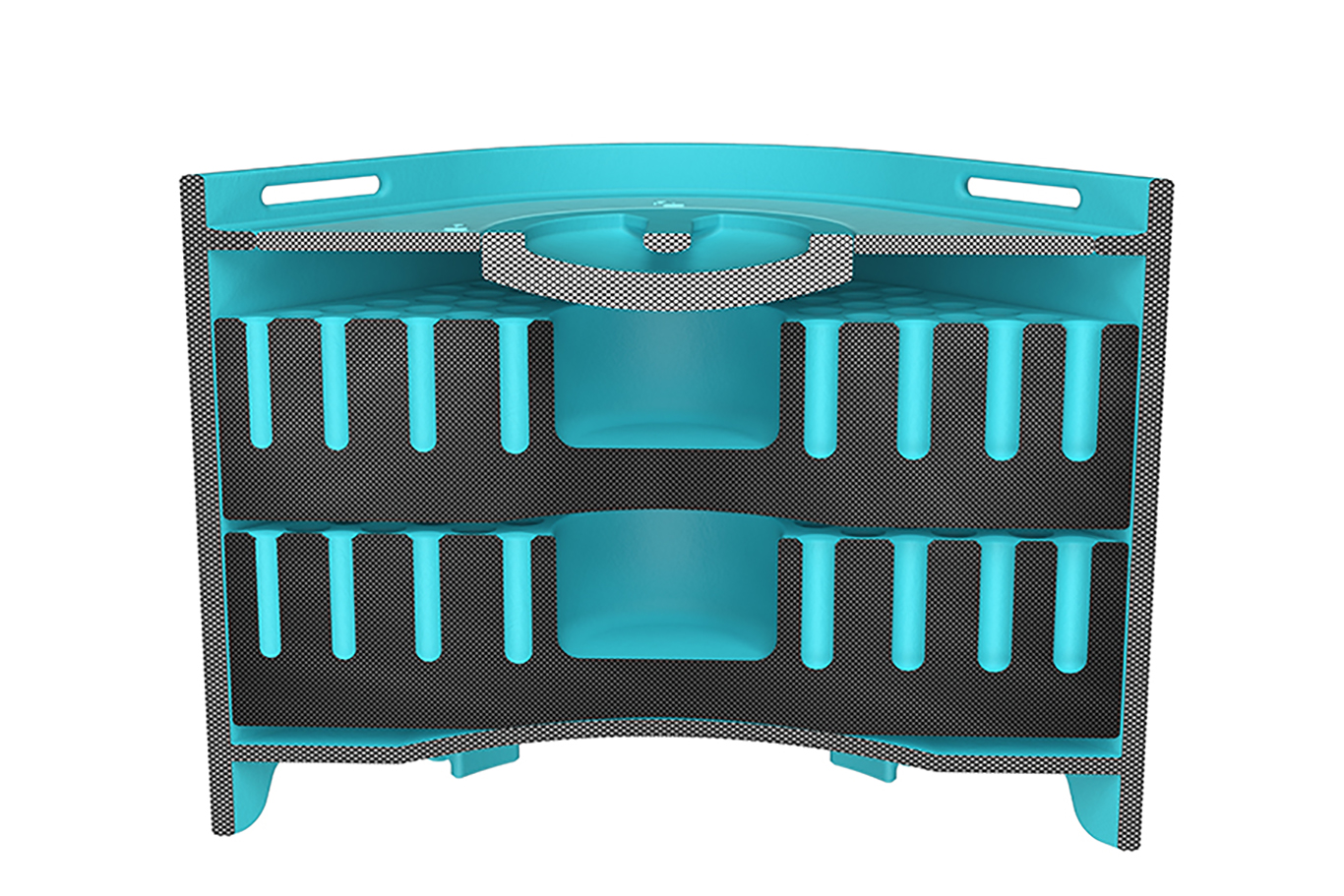

By researching all stages of the cold chain, Pakhalé created a MVC – Modular Vaccines Carrier, addressing the requirements of each stage of the cold chain. It is designed to be stackable in high volumes at the same time easy to carry in batches as well as individually to the remote locations around the world.

Keeping all the requirements of each stage during the cold chain transportation into consideration, the features of the product have been carefully studied and designed for optimal use and re-use. The outside shell of the MVC is designed for rough handling with a unique profile that holds an optimal number of vaccines and is also easy to carry under arduous conditions. The raised edges provided on the lower and upper side of the MVC make it easy to stack in a modular manner in all directions. Prominent grips and slots for straps are provided for ease of use and handling, gripping and carrying during storage, shipping and transportation in bulk as well as in batches.

With the current human condition, during the last leg of the cold chain the vaccines container is carried often by a person, sometimes on a bicycle or the back of a camel or donkey or even on foot with the container on their shoulder or head. In view of this eventuality, the bottom of the container has a concave form making it easier to carry on the head. This is one of the hidden details which help users if necessary but not an incentive for head transport.

Pakhalé focused on what he calls a ‘secular-humanistic and culturally engaging design approach’ to develop this project for a timely need around the world. MVC – Modular Vaccines Carrier is designed with current cooling technologies that are accessible and feasible for mass production worldwide.